-

Spindle ball bearings from HQW

HQW specializes in the production of spindle ball bearings made of stainless steels, and manufactures these in the highest tolerance classes. The HQW brand focuses on an inner diameter range from 3 to 25mm. These bearings are characterized by an exceptionally high lifetime, extreme corrosion resistance and suitability for the highest speeds. The quality measures in class 7 clean rooms ensure the greatest cleanliness in all stages of production. This is an important quality criterion for the production of super precision bearings, enabling us to achieve our standard of quality. With our flexible production and an inventory of many product types, we optimally address your needs during the production process.Product details

Designs of spindle bearings

In terms of design, open and sealed spindle bearings can be distinguished. In addition, one may select the ring upon which the open shoulder is produced.

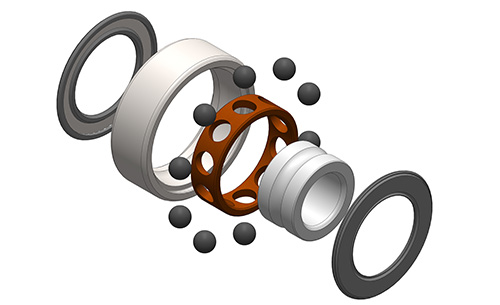

Open design

With open spindle bearings, an optimum utilization of the bearing interior with large balls and a window cage is provided. This results in maximum load carrying capacities and thus the highest lifetime. The open design is recommended for oil lubrication, as this allows relubrication via distance rings. It must be ensured that no dirt enters the bearing and that there is continuous relubrication.

Sealed design

Sealed HQW spindle bearings generally have non-contact seals on both sides, which ensures improved protection against contamination such as dust and resultant internal damage. This also impedes the leakage of lubricant. The use of seals in combination with lifetime grease lubrication is recommended. Since it is touch-free, this coverage variant does not have any influence on friction and will thus not affect the speed limit or wear, ensuring a long lifetime. HQW seals are made of fluororubber. Temperature peaks of up to 230°C are thereby possible and the material possesses a very high resistance to grease and mineral oil. Further advantages of the sealed design are simplified handling and trouble-free installation, making it particularly suitable for bearing replacement. The structural necessity of smaller balls, compared to the open design, results in a lower load capacity while simultaneously increasing the speed limit.