-

Hybrid Spindle Bearings

HQW is able to fulfill particularly high requirements with spindle bearings in the hybrid version. The inner and outer ring are made of stainless steel, the balls of silicon nitride. Hybrid spindle bearings are indicated by “HYQ” in the HQW designation system. By using hybrid bearings, the speed limit can be increased by up to 50%, as can be seen in the figure below. In addition, you can achieve a significantly higher lifetime in areas where there is inadequate lubrication. Please do not hesitate to ask our application engineers to what extent the respective advantages will affect your application.

Product details

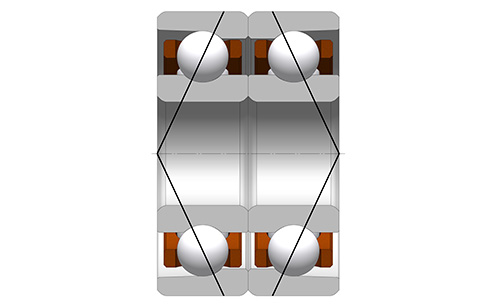

Paired spindle bearings

With rigid bearing preload, adjusted bearing pairs in back-to-back, X or tandem arrangement offer an effective, economic and technical solution for a variety of application cases.

The Back-to-back arrangement (DB): pressure lines form an O. The back-

to-back arrangement is distinguished by a broad support base and high rigid-

ity against tilting moments. The axial force is absorbed in both directions.

Face-to-face arrangement (DF): The pressure lines form an X. This bearing

arrangement is less sensitive to misalignment than the back-to-back arrange-

ment,but does, however,have less tilting rigidity. The axial force is absorbed in

both directions.

Tandem arrangement (DT): In this bearing arrangement, the pressure lines

are arranged in parallel. The axial load capacity is twice that of a single bear-

ing, but only in one direction. That is why this bearing pair must be adjusted

against another bearing or bearing pair.

Universal design (U): Universal bearings can be paired in any arrangeme-

nt according to the versions listed above. It must be noted here that the bea-

rings require the same preload.

Advantages of the universal design

• Single bearings exchangeable at identical preload force

• Can be flexibly installed in X, back-to-back or tandem arrangement or with spring preload

• Article reduction and summary of the demand possible

• Advantage in handling, as no assignment of the bearing pairs required