-

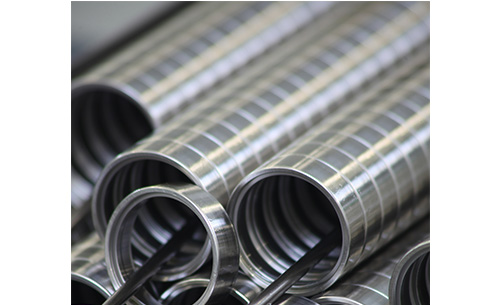

Rings

A spindle bearing is a special form of the single row angular contact ball bearing, consisting of an inner and an outer ring, a window cage and optional seals. The components of the bearing design may vary depending on the application case. The individual components are therefore selected by our application engineers according to your requirements.

Product details

Rings

HQW spindle bearing rings are manufactured inthe material X30CrMoN15-1 (HQW designation: SV30) as standard. This high-puritystainless steel consists of a very fine composition of microstructures,ensuring an improvement of the mechanical properties. The composition of thematerial can be found in the table below. For comparison purposes, thestainless steel X65Cr13 and the standard bearing steel 100Cr6 are listed; thesemay also be used upon request.

Advantages of SV30

• Longer lifetime when compared with customarymaterials

· • Highest corrosion resistance

· • Improved mechanical properties due to very finestructure

· • Very smooth running

· • High temperature resistance of up to 300°C (evenhigher temperatures also possible after consultation)

· • High chemical resistance

Application areas for SV30

· • Machine tool spindles

· • Medical technology

· • Vacuum technology

· • Aerospace

· • Measurement and control technology

· • Food and beverage industry

Corrosion resistance

· • The illustration of the degree of corrosionsubject to the passing of time underlines the extraordinary corrosionresistance of the high-performance material SV30 used by HQW, compared to the customary bearing steels 100Cr6 and X65Cr13.

· • This high corrosion resistance is alsodemonstrated by the depicted test ringss which have been tested within thescope of a salt spray test according to DIN EN ISO 9227:2012 in the in-housetest chamber under the same test conditions. The constant test conditionsinclude the concentration of the salt solution, the temperature, the pressure,and also the pH value. The test duration depends on the corrosion degree of thetest rings. Accordingly, the salt spray test of the standard steel forbearings, 100Cr6, was stopped after 50 hours due to high corrosion. Thanks tothe higher chrome content, the X65Cr13 standard steel for stainless bearingswill corrode at a much slower pace. If you have an application requiring aparticularly low corrosion degree, however, we would recommend the use of SV30steel, which showed only slight signs of corrosion after 1,000 hours of saltspray testing.